What Does Kalibraatio Mean?

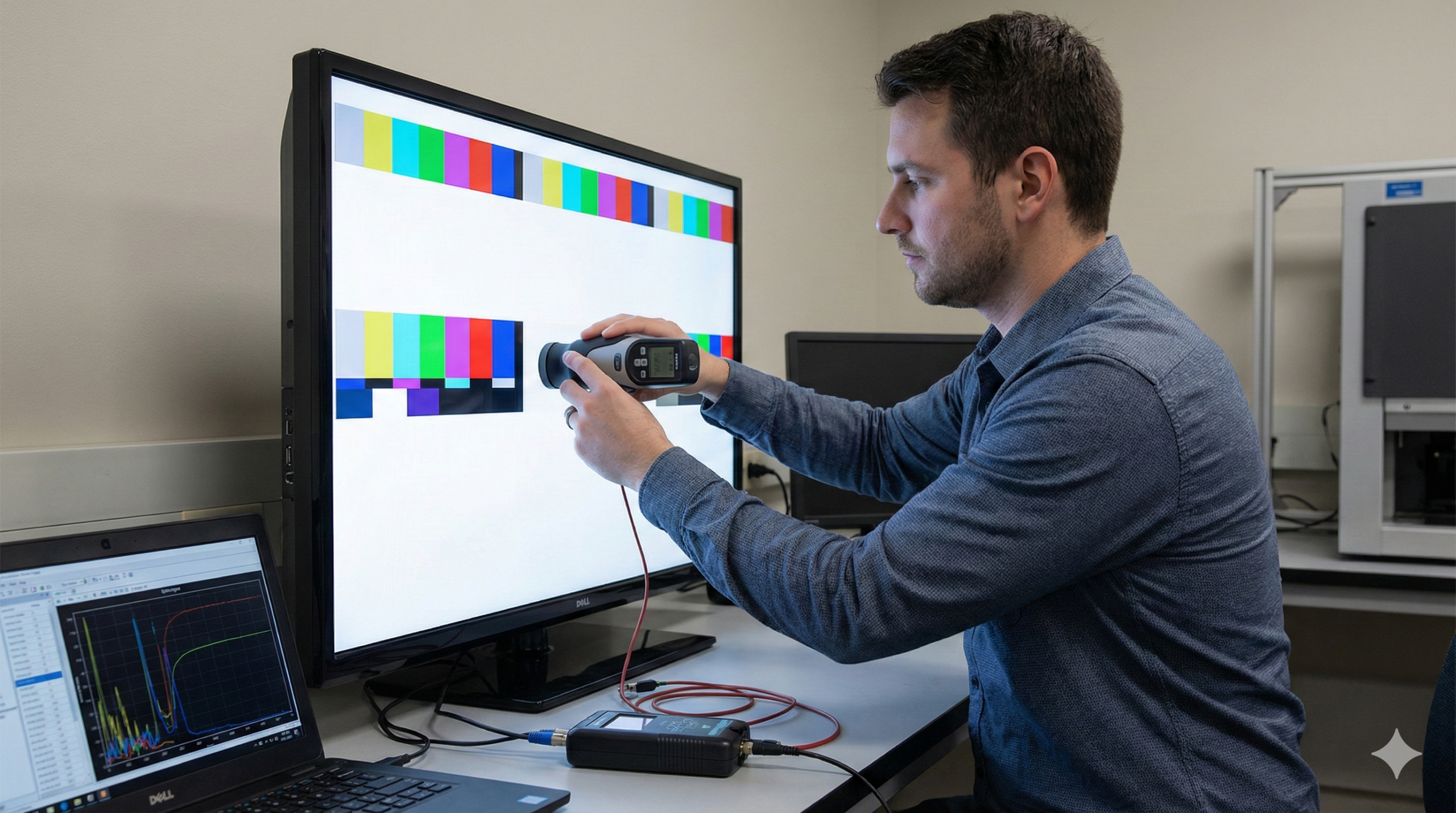

Kalibraatio is the Finnish word for calibration, a technical process used to ensure that instruments, devices, and measurement systems produce accurate and reliable results. At its core, calibration means comparing the readings of a device against a known reference standard. If there is a deviation, adjustments are made until the device produces results that fall within acceptable accuracy limits. Without proper calibration, any measurement system can drift over time, leading to incorrect data, poor decisions, or even safety hazards.

In simple terms, kalibraatio is the guarantee that the numbers you see are correct, consistent, and trustworthy. Whether it is a scale, thermometer, industrial robot, or laboratory instrument, calibration keeps the output precise.

Why Calibration Matters

The importance of kalibraatio becomes obvious once we consider how often measurements guide decisions. A medical analyzer that reads blood glucose, a fuel pump that dispenses gasoline, or a kitchen scale used in food production — all are expected to be correct. Even a small error may cause economic loss, safety issues, or legal consequences.

Calibration ensures:

- Accuracy: data matches reality

- Consistency: same results under similar conditions

- Standardization: devices meet industry or regulatory requirements

- Trust: decisions based on measurements are dependable

Without calibration, businesses could make costly mistakes, scientists could draw incorrect conclusions, and consumers could be misled.

How Kalibraatio Works — The Basic Principles

Although calibration can be complex in some fields, the basic principle is simple. A known reference standard is used to test whether a device produces correct readings. The steps typically follow a pattern:

- Select a reference standard

The reference must be significantly more accurate than the device being tested. - Measure and compare

The device is tested under controlled conditions. - Chart deviation

The difference between device output and reference value is recorded. - Adjust if needed

If deviations exceed acceptable limits, adjustments or recalibration are performed. - Document results

A calibration certificate is issued, proving the device meets accuracy standards.

This process can be routine or highly specialized depending on the application and regulations.

Types of Calibration

Kalibraatio can be applied to an enormous range of tools. The most common types include:

Mechanical Calibration

Used for physical measuring instruments such as:

- Weighing scales

- Torque wrenches

- Pressure gauges

Mechanical calibration ensures that physical forces and mass readings match accepted standards.

Electrical Calibration

Electrical instruments require precise calibration, including:

- Multimeters

- Oscilloscopes

- Power supplies

- Sensors

In industries like electronics and telecommunications, tiny electrical errors can cause major failures.

Temperature Calibration

Temperature affects almost everything, from cooking to power plants. Common calibrated devices include:

- Thermometers

- Temperature probes

- Environmental sensors

- HVAC systems

Even a difference of a few degrees can change chemical reactions, food safety, and industrial processes.

Dimensional Calibration

This category includes tools that measure size or geometry:

- Calipers

- Micrometers

- Coordinate measuring machines

Dimensional calibration is critical in manufacturing, machining, and engineering, where precision must be exact.

Calibration Methods and Techniques

There is no single method that works for every device, but common techniques include:

Direct Comparison

The device is directly compared to a reference under identical conditions. This is the most widely used and simplest approach.

Substitution Method

When a reference cannot be measured simultaneously, the reference and device are swapped in identical setups, and results are compared.

Simulation

Instead of using a physical reference, a device may be fed simulated signals to test response. This is common in electronics and communication systems.

Automated Calibration

Modern equipment can perform self-calibration using built-in sensors and software. Although convenient, periodic external calibration is still recommended.

Standards and Traceability

An essential part of kalibraatio is traceability. A measurement must be traceable to a recognized national or international standard. This ensures that a temperature reading in Finland means the same as a reading in Germany or the United States.

Traceability creates a measurement “family tree,” where each step can be verified. In regulated industries, traceability is required by law.

When and How Often Calibration Is Needed

Calibration frequency depends on multiple factors:

- Manufacturer recommendations

- Industry regulations

- Frequency of use

- Environmental conditions

- History of device stability

A device used constantly in a harsh environment may need calibration monthly, while a stable laboratory instrument may only need it annually.

Many organizations adopt a calibration schedule, documented in maintenance logs, to guarantee reliability at all times.

Real-World Applications of Kalibraatio

Calibration is everywhere, even if most people never think about it. Here are examples across industries:

Healthcare

Medical equipment must be calibrated to ensure patient safety and accurate diagnosis. This includes:

- Blood analyzers

- X-ray machines

- Infusion pumps

- Blood pressure monitors

Incorrect results can harm patients, so calibration is non-negotiable.

Food and Beverage Industry

Food production relies on precise measurements of:

- Temperature

- Weight

- Composition

Regulatory standards require calibration to maintain safety and quality.

Manufacturing and Engineering

Machines, robots, and tools must meet tight tolerances. A tiny deviation could ruin a batch of parts or cause defects.

Laboratories and Research

Scientific studies require precise measurements. Calibration ensures experiments produce trustworthy results and that findings can be reproduced.

Energy and Environment

Calibration is used for:

- Emission sensors

- Pipeline pressure

- Water quality analyzers

Regulatory compliance often depends on accurate measurement.

Benefits of Proper Calibration

Organizations that invest in proper calibration enjoy several advantages:

- Improved accuracy reduces errors and waste

- Better product quality boosts customer satisfaction

- Compliance with regulations avoids fines and legal issues

- Reduced downtime because calibrated equipment fails less often

- Increased safety for workers and consumers

Calibration is not just a technical task — it is a strategic investment.

Consequences of Poor Calibration

Failure to calibrate can lead to significant problems:

- Unsafe medical results

- Over- or under-charged customers

- Production defects

- Equipment failure

- Environmental violations

In extreme cases, the consequences may involve financial loss, brand damage, or public harm. The cost of calibration is usually far lower than the cost of mistakes.

Documentation and Certificates

After calibration, results are documented in a calibration certificate. This document usually includes:

- Device identification

- Date of calibration

- Measurement conditions

- Results and deviations

- Technician signature

- Next due date

For regulated industries, keeping these certificates is essential for audits and compliance.

Best Practices for Effective Calibration

To maintain a reliable calibration system, organizations often follow these practices:

- Use high-quality reference standards

- Keep calibration records organized

- Train personnel properly

- Maintain a calibration schedule

- Store instruments in controlled environments

- Perform checks between major calibrations

These practices ensure long-term accuracy and reliability.

Future of Kalibraatio — Smart Devices and Automation

Technology is reshaping calibration. Modern devices can:

- Self-diagnose errors

- Perform internal calibration routines

- Communicate results digitally

- Store calibration history

As automation grows, calibration will be faster, more consistent, and less dependent on manual procedures. Yet human expertise remains essential for oversight, validation, and problem-solving.

Final Thoughts

Kalibraatio, or calibration, is far more than a technical step — it is the foundation of accuracy in modern society. Wherever measurements are made, from hospitals to factories to everyday devices, calibration ensures that data can be trusted. It reduces errors, supports safety, protects consumers, and keeps businesses running smoothly.

Although the concept is simple — compare to a standard and adjust — the impact of calibration reaches across industries and daily life. Without it, measurements would become unreliable, and decisions based on those measurements could be flawed.

For anyone working with instruments, equipment, or scientific data, understanding calibration is essential. It is a process built on precision, standards, and responsibility, ensuring that every reading is meaningful, reliable, and correct.